Improper steering U-joint installation is one of the most common causes of premature wear, binding, and inconsistent steering feel in custom builds.

Whether you’re installing a double-D steering shaft or splined steering shaft, proper phasing, drilling, and set screw placement are critical for safety and performance.

Below is the correct way to install and orient steering U-joints.

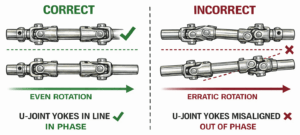

1. Proper U-Joint Orientation (Phasing)

When two U-joints are used on a steering shaft, the forks (yokes) must be aligned in phase.

Correct Orientation:

-

Both U-joint yokes are in line with each other

-

The forks are parallel

-

Shaft rotation remains consistent

Incorrect Orientation:

-

Yokes are rotated out of alignment

-

Steering input becomes non-uniform

-

Premature wear occurs

-

Steering may feel tight or notchy

Improper phasing causes uneven rotational velocity through the shaft. In steering systems, this results in inconsistent steering feedback and accelerated joint wear.

Always verify U-joints are “in phase” before final tightening.

2. Spot Drilling for Set Screws (Critical for Safety)

Set screws alone are not sufficient.

Steering shafts must be spot drilled so the set screw seats into the shaft instead of clamping against a smooth surface.

Correct Spot Drill Location:

-

0.55″ from the end of the steering shaft

-

Drill deep enough so the set screw sits below surface

-

Drill must align with the U-joint set screw location

This ensures:

-

Positive mechanical retention

-

No shaft slippage under load

-

Safer long-term operation

Failure to spot drill can result in:

-

Shaft slipping out of U-joint

-

Steering failure

-

Serious safety risk

3. Double D (DD) Steering Shaft Installation

For 3/4″ DD and 1″ DD shafts:

-

Shaft must be spot drilled

-

Use a 5/16″ diameter drill bit

-

Drill one flat side and one round side

-

Align drill location with U-joint set screw

This ensures the set screw engages properly and prevents rotational slip.

4. Splined Steering Shaft Installation

For splined steering shafts:

-

Shaft must be spot drilled to 5/16″ diameter

-

Drill once for the set screw location

-

Ensure drill aligns perfectly with set screw in the U-joint

This prevents spline movement under steering load.

5. Why Proper U-Joint Installation Matters

Steering systems are not forgiving.

Improper installation can cause:

-

Binding

-

Premature U-joint wear

-

Steering vibration

-

Loss of steering precision

-

Potential steering separation

Correct installation ensures:

- Smooth rotational transfer

- Even steering effort

- Long joint lifespan

- Mechanical safety

Common Steering U-Joint Mistakes

-

Installing joints out of phase

-

Not spot drilling shafts

-

Over-tightening set screws on smooth shaft

-

Failing to verify shaft insertion depth

-

Not checking steering rotation before final torque

Final Installation Checklist

Before final assembly:

-

U-joints aligned in phase

-

Shaft fully inserted

-

Spot drilled correctly (0.55″ from end)

-

5/16″ drill diameter used where required

-

Set screws seated below shaft surface

-

All hardware torqued properly

-

Steering rotated lock-to-lock without binding

Professional Recommendation

Correct U-joint phasing is only one part of a properly engineered steering system. To better understand how steering force is transferred through the rack assembly itself, review What Is a Power Steering Rack? for an overview of rack-and-pinion operation. If your project includes converting assist systems, our guides on Depower Hydraulic Steering Rack and Depower Electric Steering Rack (EPS Delete) walk through mechanical modifications in detail. For deeper insight into electronic assist systems and how they interact with steering input shafts, see How Does Electric Power Steering Work?, and for a system-level comparison, read Why Switch from Hydraulic to Electric Power Steering to understand design differences and performance considerations.

At ePowerSteering, we always recommend:

-

Mechanical retention (spot drill + set screw)

-

Correct U-joint phasing

-

Inspection before final installation

-

Testing steering input before road use

Steering is a safety-critical system — installation shortcuts are not worth the risk.

Leave A Comment