What Does It Mean to Depower a Hydraulic Rack?

Depowering a hydraulic power steering rack converts it into a manual steering rack by removing hydraulic assist functionality.

This is common in:

- Vehicles planning for aftermarket column mounted electric power steering.

-

Track cars

-

Engine swaps

-

Weight reduction builds

-

Simplified race setups

How Hydraulic Power Steering Works

A hydraulic rack uses:

-

Internal piston

-

Hydraulic chambers

-

Torsion valve or servo assembly

-

Power steering pump

-

High-pressure lines

Fluid pressure assists steering when the torsion valve or servo opens and directs fluid to either side of the rack piston.

Three Common Ways to Depower a Hydraulic Rack

Method 1: Loop the Lines (Temporary or Budget Method)

This involves:

-

Removing pump

-

Looping pressure and return ports together

Pros:

-

Quick

-

Cheap

-

No internal disassembly

Cons:

-

Hydraulic piston still creates drag

-

Steering can feel inconsistent

Looping hoses is not true depowering — it only disables assist.

Method 2: Loop the Lines through a Catch Can

This involves:

-

Removing pump

-

Looping pressure and return ports through a catch can

Pros:

-

Quick

-

Cheap

-

No internal disassembly

- Less pressure in the rack

Cons:

-

Hydraulic piston still creates drag

-

Steering can feel inconsistent

Looping hoses through a catch can is not true depowering — it only disables assist.

Method 3: True Internal Depowering (Recommended)

This is the proper method.

Step 1: Disassemble Rack

-

Remove inner tie rods

-

Open rack housing

-

Remove hydraulic piston seals

-

Remove or modify internal torsion valve components.

Step 2: Remove the Hydraulic Piston Ring

Inside the rack is a ring or piston seal assembly that divides hydraulic chambers.

This must be removed or modified so fluid pressure cannot build resistance.

This eliminates hydraulic drag.

Step 3: Weld or Pin the Torsion Bar (If Applicable)

Some racks require:

-

Welding torsion valve internally

-

Pinning torsion mechanism

-

Converting it to solid mechanical input

This prevents excessive play.

Step 4: Reassemble as Manual Rack

-

Clean thoroughly

-

Use original hydraulic fluid as a lubricant.

-

Ensure smooth rack movement

-

Cap or plug ports

Why True Depowering Is Better

Compared to looping lines:

- Eliminates hydraulic drag

- Provides consistent steering feel

- Reduces weight

- Improves reliability

- Cleaner engine bay

Safety Considerations

Improper depowering can cause:

-

Excessive steering play

-

Internal rack wear

-

Seal failure

-

Steering bind

Not all hydraulic racks are ideal candidates for conversion.

Should You Depower Your Rack?

Ask yourself:

-

Is this a race car?

-

Are you removing the power steering pump anyway?

- Have you decided to install a column mounted electric power steering system?

If the answer is yes, true depowering can be a clean solution.

Need Technical Help?

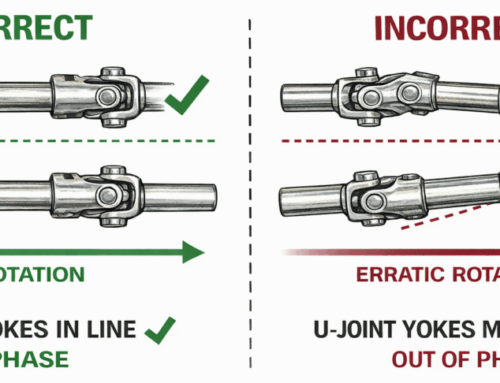

If you’re converting a hydraulic rack to manual operation, it helps to understand how rack-and-pinion systems are designed from the factory. Our article What Is a Power Steering Rack? breaks down the internal components that make up both hydraulic and electric assemblies. If you’re debating whether to depower or upgrade instead, see Why Switch from Hydraulic to Electric Power Steering to compare system advantages. Builders working with electronic systems should also review How Does Electric Power Steering Work? for a technical overview of torque sensors and assist motors. And if your conversion involves steering shaft modification, our guides on Depower Electric Steering Rack (EPS Delete) and Steering U-Joint Phasing & Installation provide additional best practices for safe and reliable steering setups.

Leave A Comment