What Does It Mean to Depower an Electric Steering Rack?

Depowering an electric power steering (EPS) rack means converting it from assisted steering to full manual operation. This is commonly done in race cars, engine swap builds, kit cars, custom projects where power assist is unnecessary or undesirable, and vehicles being converted to column mounted electric power steering.

Unlike hydraulic systems, electric racks use a motor and reduction gear to provide assist. When depowered correctly, the rack functions mechanically like a manual steering rack.

Why Depower an Electric Rack?

Common reasons include:

- Converting to column mounted electric power steering

-

Engine swap eliminates factory EPS control module

-

Race car build (weight reduction and simplicity)

-

Drift applications

-

Reliability in off-road or endurance racing

-

Custom chassis integration

-

Removing electronic steering faults

For many builders, deleting the EPS motor simplifies wiring and reduces failure points.

How an Electric Steering Rack Works

An EPS rack typically includes:

-

Steering input shaft

-

Torsion bar torque sensor

-

Electric assist motor

-

Reduction gear assembly

-

Rack and pinion mechanism

-

Control module (internal or external)

The electric motor applies torque to the rack based on driver input.

When you remove the motor properly, the rack still mechanically connects the steering wheel to the wheels, but without assist.

How to Depower an Electric Steering Rack

⚠️ This procedure is intended for experienced builders and motorsport applications. Improper modification can result in unsafe steering conditions.

Step 1: Remove the EPS Motor Assembly

-

Remove rack from vehicle

-

Remove electric assist motor

-

Remove reduction gear assembly (if applicable)

-

Inspect internal gear engagement

Step 2: Install a Block-Off Plate

After motor removal:

-

Fabricate or install a machined aluminum block-off plate

-

Apply RTV silicone sealant to prevent moisture intrusion

-

Ensure proper torque on fasteners

-

Verify no debris enters rack housing

This prevents contamination and maintains structural integrity of the rack housing.

Step 3: Inspect Internal Components

You must verify:

-

Torsion bar integrity

-

No binding inside rack

-

Proper mechanical connection remains intact

Some racks require internal locking of the torsion bar to eliminate excessive play. This varies by manufacturer.

Professional Depowering vs DIY

At ePowerSteering, we recommend:

-

Properly machined block-off plates

-

Sealed housing to prevent contamination

-

Internal inspection before reuse

-

Testing rack travel and preload

Improper depowering can cause:

-

Excessive steering play

-

Binding

-

Rack damage

-

Safety hazards

Final Thoughts

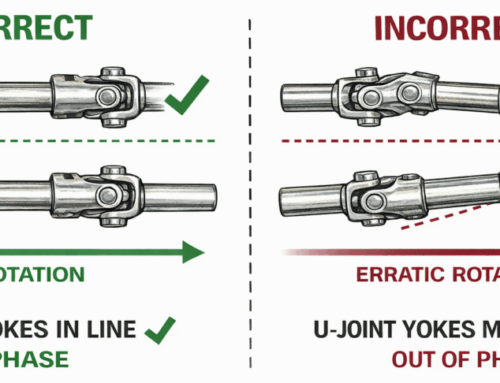

Before removing assist components from an electric rack, it’s important to understand how the system functions in its original configuration. Our guide How Does Electric Power Steering Work? explains the interaction between torque sensors, control modules, and assist motors. If you’re comparing manual conversion versus system upgrades, review Why Switch from Hydraulic to Electric Power Steering to understand the broader benefits of EPS technology. For foundational knowledge of rack architecture, see What Is a Power Steering Rack?, which covers both hydraulic and electric designs. Builders working across multiple steering types may also want to read our Depower Hydraulic Steering Rack guide, along with Steering U-Joint Phasing & Installation, to ensure proper shaft alignment and mechanical integrity during any steering modification.

Depowering an electric steering rack can be an excellent solution for race cars and custom builds — when done correctly.

Leave A Comment